Bluelight LED Equipment

European patent: EP2 2 129 956 B1

LED Head 144

Length of Push-rod

40m

Diameter-Range

100mm – 125mm (F-Liner Std)

70mm – 150mm (F-Liner 3D)

Input Power – 292.3W

Output Power – 200.4W

Efficiency at 50 degrees celsius – 69%

Length of the light source – 5.2cm

Width/Diameter of the light source – 4.1cm

Wight of the light source – 79g

Output power/weight – 2.5W/g

Number of diodes per light source – 144pcs

Manufacturer diodes – Osram

Operating temperature diode – -40 … 120ºC

Junction temperature of absolute diode – 150ºC

Wavelength – 444 … 457nm

Viewing angle – 120º

LED Head 336-2

Length of Push-rod

40m

Diameter-Range

100mm – 225mm (F-Liner Std)

100mm – 150mm (F-Liner 3D)

150mm – 225mm (F-Liner 3D)

~

Input Power – 705.6W

Output Power – 470.4W

Efficiency at 50 degrees celsius – 66.7%

Length of the light source – 6.5cm

Width/Diameter of the light source – 5.2cm

Wight of the light source – 165g

Output power/weight – 2.9W/g

Number of diodes per light source – 336pcs

Manufacturer diodes – Osram

Operating temperature diode – -40 … 120ºC

Junction temperature of absolute diode – 150ºC

Wavelength – 444 … 457nm

Viewing angle – 120º

LED Head 696

Length of Push-rod

100m / 50m

Diameter-Range

100mm – 400mm (PAA-F-Liner)

150mm – 600mm (PAA-G-Liner)

Input Power – 1,461.6W

Output Power – 974.4W

Efficiency at 50 degrees celsius – 66.7%

Length of the light source – 13.2cm

Width/Diameter of the light source – 5.2cm

Wight of the light source – 375g

Output power/weight – 2.6W/g

Number of diodes per light source – 696pcs

Manufacturer diodes – Osram

Operating temperature diode – -40 … 120ºC

Junction temperature of absolute diode – 150ºC

Wavelength – 444 … 457nm

Viewing angle – 120º

LED Head 144

Length of Push-rod

40m

Diameter-Range

100mm – 125mm (F-Liner Std)

70mm – 150mm (F-Liner 3D)

Input Power – 292.3W

Output Power – 200.4W

Efficiency at 50 degrees celsius – 69%

Length of the light source – 5.2cm

Width/Diameter of the light source – 4.1cm

Wight of the light source – 79g

Output power/weight – 2.5W/g

Number of diodes per light source – 144pcs

Manufacturer diodes – Osram

Operating temperature diode – -40 … 120ºC

Junction temperature of absolute diode – 150ºC

Wavelength – 444 … 457nm

Viewing angle – 120º

LED Head 336-2

Length of Push-rod

40m

Diameter-Range

100mm – 225mm

~

Input Power – 705.6W

Output Power – 470.4W

Efficiency at 50 degrees celsius – 66.7%

Length of the light source – 6.5cm

Width/Diameter of the light source – 5.2cm

Wight of the light source – 165g

Output power/weight – 2.9W/g

Number of diodes per light source – 336pcs

Manufacturer diodes – Osram

Operating temperature diode – -40 … 120ºC

Junction temperature of absolute diode – 150ºC

Wavelength – 444 … 457nm

Viewing angle – 120º

LED Head 696

Length of Push-rod

50m / 100m / 125m (pull in only)

Diameter-Range

100mm – 400mm (PAA-F-Liner)

150mm – 600mm (PAA-GF-Liner)

Input Power – 1,461.6W

Output Power – 974.4W

Efficiency at 50 degrees celsius – 66.7%

Length of the light source – 13.2cm

Width/Diameter of the light source – 5.2cm

Wight of the light source – 375g

Output power/weight – 2.6W/g

Number of diodes per light source – 696pcs

Manufacturer diodes – Osram

Operating temperature diode – -40 … 120ºC

Junction temperature of absolute diode – 150ºC

Wavelength – 444 … 457nm

Viewing angle – 120º

CIPP lining systems available

- PAA-F-Liner standard, DIA100-400mm, flexible liner based on synthetic fibre with PU-coating, to be used in laterals or inside buildings, mains styrene-free VE-resin, one diameter expansion possible, inversion-process, more than 700km have been installed throughout Europe.

- PAA-F-Liner 3D, DIA100-150mm, DIA150-225mm, DIA225-300mm flexible liner based on synthetic fleece with high radial expansion and PU-coating, to be used in laterals or inside buildings, styrene-free VE- resin, diameter expansion possible from 100mm to 150mm, 150mm to 225mm, 225mm to 300mm inversion-process.

- PAA-GF-Liner LED, DIA150-600mm, non flexible grp-liner for mainly straight lines, styrene-free VE-resin, no diameter changes possible, pull-in-process.

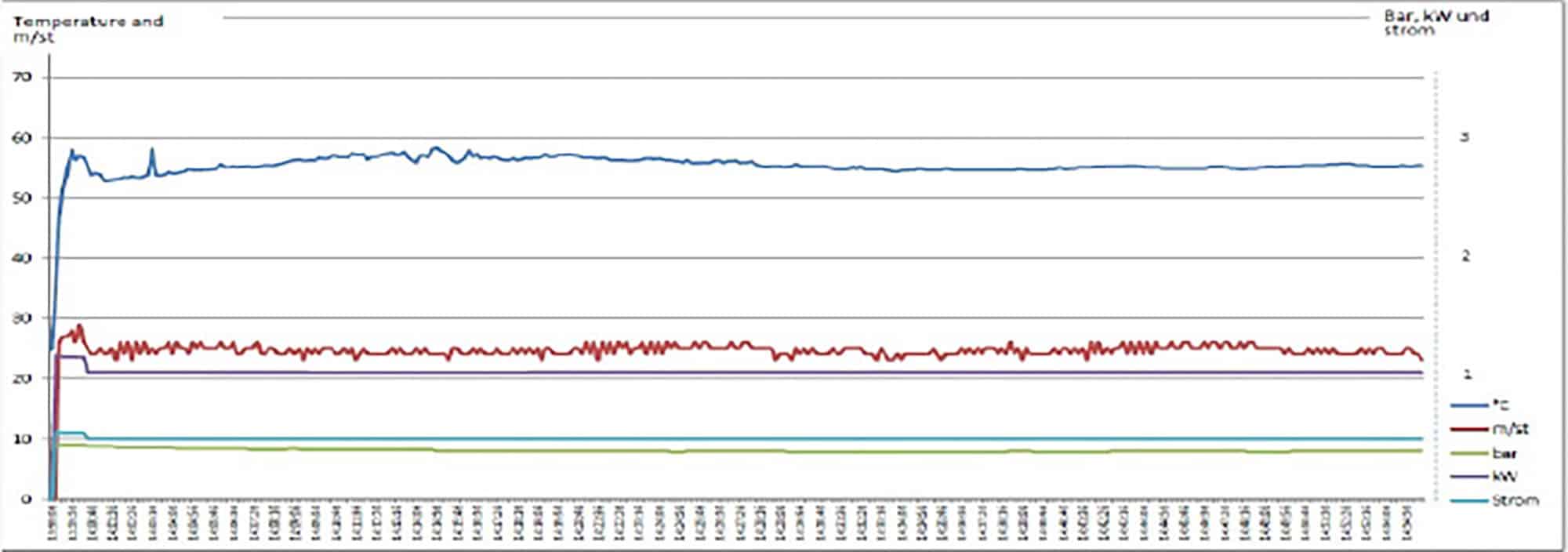

Documentation of curing parameters

- Liner installation is two to fives times more efficient

- Possibility to check the liner before curing using the integrated camera on the LED head

- Storage of up to 3 months for PAA-F impregnated liners and 12 months for PAA-GF impregnated liners

- Fully automated quality assurance and documentation of all relevant parameters

- Instruction manual including definitions of all procedure steps

- Low space requirement for the installation equipment with maximum equipment mobility

- Fully software controlled system technology

- Reduction of error potential compared with multi-component systems

- Maximum flexibility thanks to a choice of impregnating on site or using pre impregnated materials

- User support by a global player in trenchless renovation of drainage systems; remote maintenance and remote sessions are possible

- Less waste (re-usable silicone calibration hoses) excess resins from impregnation can be re-used