While light curing of non-flexible pipe liners in sections and main sewers has undoubtedly been a standard technique for more than a decade, light-curing processes for curing flexible pipe liners for property drainage have only established themselves in the market in recent years.

Per Aarsleff A / S, the Bluelight process – based on flexible synthetic fiber carriers, styrene-free vinyl ester resin and patented LED curing in the wavelength range of blue light – was brought to product maturity from 2008 to 2014. With the establishment of Bluelight GmbH, the system was initially available to German-speaking market areas from 2016 as part of a B2B concept. A little later, the Bluelight concept was also transferred to Central and Southern Europe. In a final step, the technology is now available worldwide through licensees.

In Europe alone, the Bluelight LED system now has the impressive experience of almost 750,000meters of installations, and 100,000 individual installations. Including installations from Per Aarsleffs own installation crews as well as Bluelight GmbH users.

At the end of 2020, 171 active Bluelight supply and control units as well as 377 curing units were active worldwide, about 40 percent of them within the area of responsibility of Bluelight GmbH.

Bluelight sees itself as a system provider: Bluelight light sources are only intended and suitable for curing its own pipe liners (PAA-F-Liner) and (PAA-G Liner). Both the device technology and the resin are patented and only available as a package. The Bluelight resin was specially developed for this application and wavelength range. Liners can be ready impregnated. The wavelength of the light-curing resin is in the range of visible blue light at 450nm. It is – contrary to repeated false assumptions or statements – not UV light.

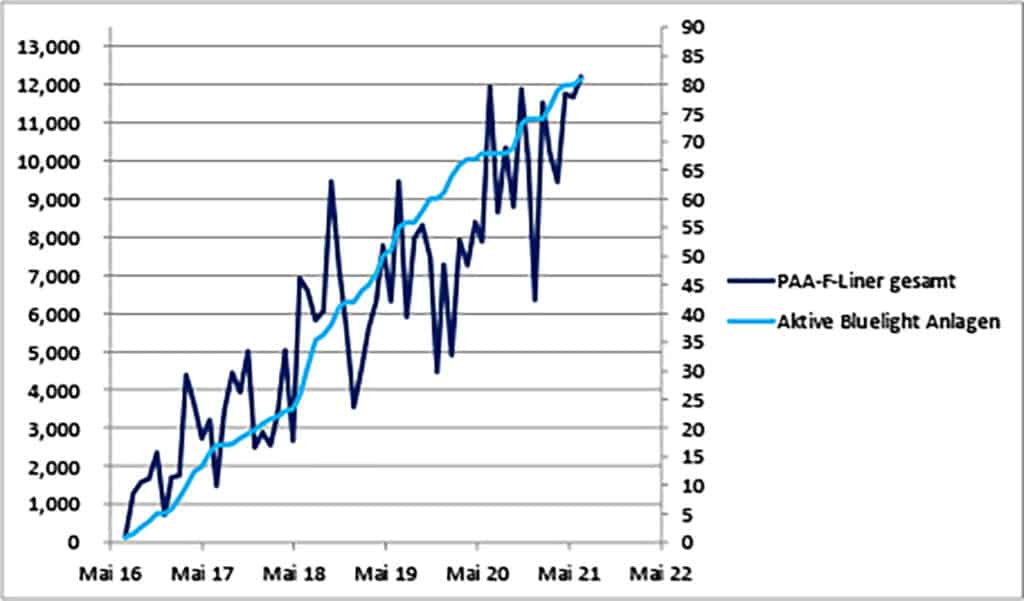

Graphic: Business development of Bluelight GmbH | Ratio of active Bluelight LED systems and installed PAA-F liner meters per month

Graphic: Business development of Bluelight GmbH | Ratio of active Bluelight LED systems and installed PAA-F liner meters per month

In 2019, KOB / Brawoliner reacted to the new trend and expanded its own product portfolio to include a light-curing version. The Brawoliner, which is established on the market, was expanded by a light-curing version. Brawoliner started as an open system and initially envisaged curing its own liner with different curing systems from other manufacturers. From 2020, however, Brawoliner adapted the strategy and also went over to a system provider model: Meanwhile, Brawoliner also offers its own system as a combination of its own Magnavity LED curing technology with its own liner technology. Brawoliner cannot yet be purchased impregnated. The wavelength of the light-curing resin is in the UV range (<= 400nm).

What are the success criteria for light curing in property drainage? The light curing of pipe liners in property drainage offers …

- higher speed than heat curing,

- high process reliability and lower error potential,

- a system-dependent storage stability of the pipe liners,

- Depending on the system, the option to purchase factroy impregnated liners or impregnation on site.

- potential savings in fuel costs compared to hot curing and better CO2 balance,

- lowest emissions in terms of noise or odours

- minimal waste

- a highly portable technology.

The Bluelight LED system has proven to be reliable, robust and sustainable in the market. Initial skepticism towards the “supposedly new” technology gave way with the steadily increasing number of satisfied users and end customers, as well as due to more and more successfully implemented measures and projects.

How do the pipe liners (PAA-F Liners) harden with the Bluelight LED System? Bluelight GmbH answered this question in 2020 with residual methacrylate provisions. Classic light curing works by polymerization. For unsaturated styrene-containing polyester resins (mainly used in the main channel), the determination of the residual styrene content can serve as an indicator of the degree of curing. The target value is <= 2 mass%. Styrene-free vinyl ester resins (mainly used in property drainage) contain methacrylates or acrylates instead of styrene. The Institute Siebert und Knipschild (S&K) has been able to determine residual methacrylate contents in liner samples since 2020. As part of the annual DIBT monitoring site, Bluelight GmbH will then have the residual methacrylate content determined at the site samples obtained since 2020. In addition, in cooperation with S&K, residual methacrylate contents were determined on further PAA-F-liner samples hardened with Bluelight.

The residual methacrylate content of the PAA-F liners cured with Bluelight LED technology ranges from 0.1% to 0.2%. In terms of the quality of the curing, they are comparable to the residual styrene content of hot-cure liners and even better (lower) than the residual styrene content of UV light-curing GRP liners that can normally be achieved.

However, the Bluelight results for the PAA-F-Liner are purely system-specific. They are not generally valid for other systems or even combinations of curing technology and resins.

However, the results show that excellent curing can be achieved with LED curing if the lighting technology has been optimally matched to resin and carrier material, sufficient light intensity is available for curing and curing speeds have required securities.

In addition, Bluelight GmbH are the only system provider with the main area of application in property drainage repeatedly submitted to the IKT Liner Report. After 2018, Bluelight GmbH again achieved 100% in all test categories with the LED-curing PAA-F liner in the 2020 report. As a system provider, Bluelight GmbH is not audited by the customer without processing work contracts. Therefore, samples for the liner report were collected at various construction sites of the own demonstration and rental plant – exclusively by Bluelight application technicians – . The result shows that the system technology can reach 100%, provided that the employees know 100% how to proceed during installation, curing and sampling.

Can the experiences and successes of LED technology also be transferred to light curing of pipe liners for larger nominal widths? And shouldn’t LED technology also be used for curing non-flexible GRP pipe liners in main channels? Does the UV LED curing of GRP/UP liners work at all?

In social media there are repeated advertising promises with the corresponding message: With UV-LED diodes, any standard GRP pipe liner can (allegedly) be cured with styrene-containing unsaturated polyester resin. UV LED diodes could (allegedly) replace the existing UV gas discharge lamps.”

Does this claim consist of a fact check? As of August 2021, no UV-LED light source was approved by a GRP pipe liner manufacturer for DIBT-compliant curing of UV-curing GRP pipe liners. The DIBT approvals do not cover UV LED curing.

Due to the aforementioned advertising promises, Bluelight GmbH repeatedly received inquiries from its own users, whether with modified device technology (LED diodes in the UV range <= 400nm instead of in the blue light range = 450nm) the curing of light repeatedly claimed by others is not possible.

In coordination with Per Aarsleff A/S, a cylindrical prototype equipped with UV LED diodes was built for clarification. The cylinder shape was chosen to achieve the longest possible exposure time at maximum intensity.

In March 2020, the PAA G-Liner standard with styrene-containing UP resin in different speed ranges (20, 30, 40, 50, 60 m/h) was hardened with this prototype for UV light curing.

Residual styrene levels were determined in an external laboratory for plastics technology. These were between 5.4% and 10.3% of the total application and thus significantly too high compared to the usual results with conventional UV curing (target <= 2%).

As a result, the following should be noted:

- UV-LED diodes do NOT achieve complete qualitative curing of the UV-curing liner impregnated with styrene-containing polyester resin currently available on the market.

- In order to completely polymerize these liners, the photo initiators currently used would first have to be modified specifically to the wavelength of the LEDs.

- LED diodes provide hardly any heat energy compared to UV gas lamps, which is obviously required for polymerization of styrene-containing UP resins with standard photo initiators.

A further aspect of the light-curing flexible pipe liners for use in property drainage was “ring gap formation”. In this regard, the question was raised as to whether an annular gap-free installation with flexible light-curing pipe liners and styrene-free VE resin can be realized.

In the summer of 2019, RS-Technik AG first published a report on a successfully carried out test for “rear-travel-free house connection renovation (using hose liners) with epoxy resins”. The proof of the watertight connection of the RS MaxLiner epoxy resins to plastic and cast pipes was demonstrated in the test. The rehabilitation goal of the watertight and trailing connection was achieved via the connection of the liner with the pipe.

The design was successfully carried out for a selection of plastic and cast pipe materials. The test was accompanied and documented by experts.

After knowledge of the experiment initiated by RS-Technik, Bluelight GmbH decided to test its own light-curing system PAA-F-Liner LED equally. It had to be clarified whether a positive test result could be achieved due to the lower adhesive effect and the chemical volume shrinkage of the styrene-free vinyl ester resins compared to epoxy resins. The test was accompanied and documented by experts. The test set-up included complete greasing of the previously roughened tubes, high-pressure cleaning, liner cleaning and curing, as well as drilling the outside of the tube with attachment of test hoses and filling with test liquid to build up a water column.

The result was an annular gap-free installation of the PAA-F liner during curing with Bluelight LED light sources depending on the pipe materials. Chemical volume shrinkage occurs due to curing overpressure on the inner liner side and does not lead to an annular gap between liner and old pipe.

As a result, the following should be noted:

- Pipe liners with styrene-free light-curing vinyl ester resins can be installed ring-gap-free under certain defined conditions depending on the old pipe material.

- In order to reproduce the test result, a sufficient adhesive base must be produced in advance and the old pipe material must be precisely known.

- he waiver of subsequent connection work at pipe ends or side inlets is not a DIBT approval component.

- The static design concept according to DWA-A 143-2 is based on a positive-fit pipe liner. According to the current static design concept of the DWA, a force or material adhesion cannot be calculated by the algorithms of the available standard software.

Last but not least, the topic of light-curing epoxy resins will be highlighted. Is light-curing epoxy resin possibly the future?

In social media, there are repeated advertising promises such as: ‘Light-curing epoxy resin is the future in property drainage, as it would (allegedly) glue. “Various suppliers boast to have corresponding resins on offer.

The topic is also mentioned here and there in technical articles, but with a little more restraint than on Facebook or LinkedIn. What are the current facts?

As of August 2021, there is no DIBT approval for a tube liner system based on light-curing epoxy resin. There are also no registrations outside Germany.

Bluelight GmbH has intensively tested and evaluated light-curing epoxy resins in coordination with Per Aarsleff A/S. After the first unsuccessful experiments, functioning solutions are now available under laboratory conditions.

What are the advantages of light-curing epoxy resin over the proven styrene-free light-curing VE resins?

Light-curing styrene-free PU resin

Selling price / Market price 13 – 17 € / kg *

E-module short-term 2,200 – 3,200 N/mm2

Bonding generally possible, can be modified

Shrink Volume shrinkage about 4-6%, but depending on the carrier material without impact, risk of thermal shrinkage

Light-curing EP resin

Selling price / Market price 25 – 45 € /kg *

E-module short-term 950 – 1,600 N/mm2

Bonding very possible

Shrink Low volume shrinkage, but risk of thermal shrinkage

According to the current state of the art, light-curing epoxy resin can be useful in the future in flexible pipe lining in the domestic area, since no minimum ring stiffness is required there and the resin consumption per meter is low. The currently available resins are not suitable for wide use in property drainage.

Summary

The light curing of flexible pipe liners has arrived in the small nominal widths of the plot drainage and has successfully established itself there. There are well and safely functioning techniques. However, general and special application limits and areas of application must be carefully observed. In order to ensure optimally coordinated solutions, system provider models seem to prevail in land drainage. Any combination of hardening technology, pipe liners and resins, however, have so far been classified as questionable and possibly even dangerous, especially since for wild combinations neither a complete initial and aptitude test is still a DIBT approval.

Further developments are to be expected. However, by far not everything that is touted as a future here and there already works. A critical examination of overly optimistic advertising promises is worthwhile.

PBF Drainage are the UK sales agents for the Bluelight system and materials, carrying out ongoing training, ongoing investments into Bluelight equipment means that clients can use our hire equipment once trained, until they generate work volume to warrant purchasing additional equipment of their own.

Working with existing and new contractors within the UK has benefitted the industry by increasing quality and providing the end client with a high quality, long lasting finished product. This increased quality is what should be provided to all customers due to the severe implications of failed drainage.